HOME > MACHINES > Shot Blasting

Shot Blasting

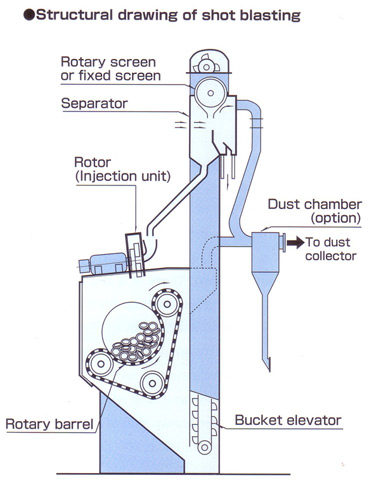

Unlike air blasting, shot blasting does not use compressed air as the power for injecting abrasive media. The shot blasting uses motor rotation to rotate blades at a high speed. Abrasive media are forcibly fed to the blades and injected at high speed by the blade rotation.

The injection unit is normally called a "rotor" (sometimes called an impeller). There is a big difference between shot and air blasting. Shot blasting injects a far larger amount of abrasive media with less power. A comparison of the injection processes between one nozzle with a three-horsepower compressor and one rotor with a three-horsepower motor shows that shot blasting injects abrasive media 50 to 100 times that of air blasting per minute. (The value will vary depending on condition.)

power.

For the mechanism, a shot blasting machine generally includes devices such as a bucket elevator and a screw conveyor to forcibly circulate larger abrasive media. (If the weight of your abrasive media is heavy, the media cannot be transferred by the suction force of a dust collector unlike air blasting.)