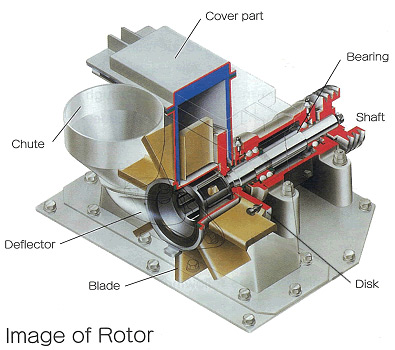

Rotor

A rotor consists of three main sections : a rotary section with blades that blow abrasive media, a feeding section for supplying abrasive media to the rotor, and a cover section composing the rotor itself. The rotor blades, which are worn as well as the nozzles, consist of special cast iron and heat treated parts.

Some rotors use ceramic blades. The number of blades is normally 8 but sometimes 2 to 4. Each blade is an insertion/extraction type for replacement when worn out. The entire set of blades should be replaced at the same time because the weight difference from abrasion causes vibration and noise.

Other components are as follows: a deflector (distributor) to change the injection angle of the abrasive media, a shutter gate to limit the feeding of abrasive media, a cover for the whole unit, protection plates for the internal surfaces of the rotor, a disk for positioning the blades, a rotary shaft bearing, etc

Separator

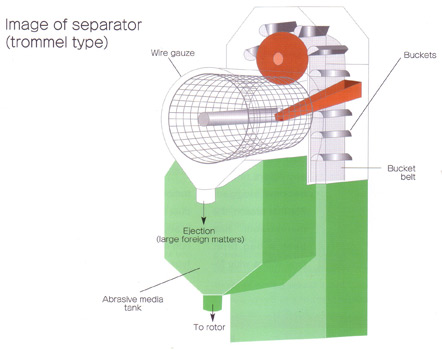

A separator works like a cyclone for an air blasting. It separates foreign matter mixed into the injected abrasive media and the media that gets smaller after beig broken. Various separation methods are available but selection by wind force is basically used.

(The following characteristics are utilized with the suction force from a dust -collector : the lighter weight of abrasive media, the farther media are drawn, and the heavier weight the earlier media falls before drawn into the distance.)

In addition, the following selection techniques are efficiently combined for this process. For a trommel type (sometimes called a rotary screen type), a wire gauze mesh attached to the rotary drum separates the abrasive media based on particle sizes, and then the media are separated based on their specific gravity by the suction force from the dust collector.

For a vibration screen type, a vibrating mesh separates the media. The media are then further separated based on specific gravity by suction force as well. Also, a magnetic type, a vibrating screen type, etc., are available. Select the appropriate type of abrasive media for separation.